The Intermittent failures in fiber optic links represent one of the most common challenges for network and maintenance engineers. In these cases, the connection may exhibit variable attenuation levels without an apparent cause, which complicates the diagnosis and extends the troubleshooting time.

In most scenarios, the root of the problem lies in two factors that constantly compete for control of the optical signal: fiber optic connector geometry and surface contamination.

The performance of a fiber optic connection depends largely on the connector geometry, which is defined by critical parameters such as the radius of curvature, the Apex Offset and the Fiber Height.

An incorrect polishing can cause:

These defects directly affect the light coupling between fibers.

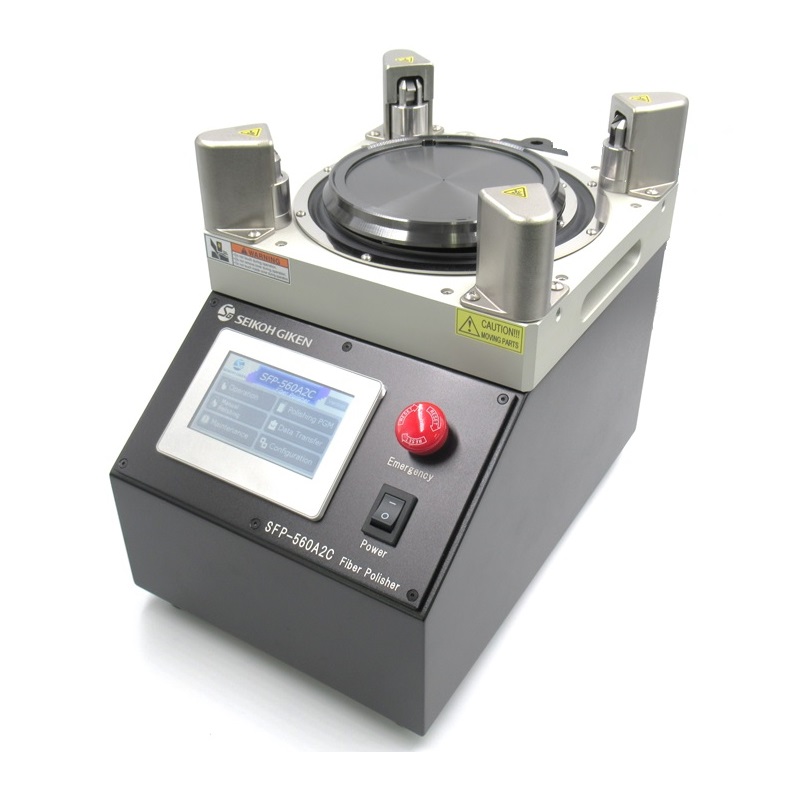

Precision polishing equipment, such as those used in professional manufacturing environments (for example, those from Seikoh Giken), allow for the precise control of these parameters. Therefore, when a connector comes from a well-calibrated polishing process, the probability that high attenuation is due to a geometric error is low.

In those cases, it is advisable to focus the diagnosis on the other most frequent cause: contamination.

The dust, the fingerprints, the cleaning residues or even the humidity can settle on the fiber optic connector end-face and alter signal transmission.

A microscopic particle located at the center of the core can:

Various studies indicate that over 80% of failures in optical networks are due to dirty connectors, making contamination the primary cause of performance issues, even ahead of manufacturing defects.

When an intermittent failure or unusual signal loss occurs in a fiber optic system, it is recommended to follow a ordered diagnostic sequence that allows simple causes to be ruled out before moving on to more complex inspections.

1. Visual Inspection: The Root of Contamination

Use an inspection probe or inspection microscope is the critical first step. Most attenuation problems are caused by contamination on the connector end-face (dust, oil residues, or lint).

Key Tool offered by Repstronics: At this stage, inspection microscopes Domaille Optispec from Fiber Optic Center make it easy to accurately identify fiber contaminants and defects, ensuring that inspection standards are met.

2. Controlled Cleaning: Precise Action

Apply cleaning using specialized tools and consumables specifically designed for fiber optics. is the next step.

Repstronics Solution: cleaning must be performed with tools designed for fiber optics, such as liquid cleaners, lint-free wipes, or mechanical devices. For this, you can count on the line of Cleaning products Seikoh Giken (Handimate, Ferrule Mate y Ferrule Pro), which offers efficient and safe solutions to remove residues without leaving traces, preparing the connector for optimal measurement.

3. Reassessment: Verifying Success

After cleaning, it is crucial to re-measure optical lossIf the attenuation has disappeared or has been reduced to acceptable levels, the problem was successfully resolved through cleaning.

4. Geometric Analysis: Deep Evaluation

If attenuation persists even after rigorous cleaning, you must move on to a more technical review. Verify the connector geometry with an interferometer or advanced inspection equipment can reveal physical problems such as scratches, incorrect polishing, or structural defects.

Connector geometry and surface cleanliness are the two factors that most influence optical signal stability. When connectors are manufactured using precision polishing equipment, intermittent failures are typically rooted in contamination rather than structural defects.

Therefore, the first step in any attenuation diagnostic must always be a rigorous cleaning. Only after eliminating the possibility of contamination does it make sense to evaluate geometric parameters. Field experience confirms that, in most cases, dirt is the one truly winning the fight for the signal.